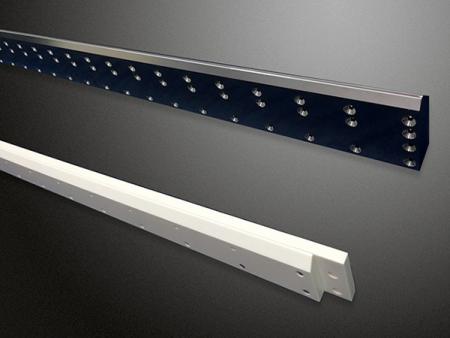

Air Knife

Water Knife

The working principle of the air knife is to use the gas to enter the main body of the air knife and blow it out evenly through the air outlet gap at the front edge of the air knife to scrape the surface liquid of the glass substrate product. It can also be applied to other industrial needs. SHEN-YUEH has developed air knife test equipment; each knife passes strict repeated tests of wind pressure and water curtain. Test reports and dynamic test videos are delivered with the products.

Air Knife Maintenance Services

We also provide air knife maintenance services whereby used air knives can be restored to an almost new state to extend service life, and reduce costs for customers. We also provide air knife internal consumables services so customers can replace parts themselves.

SHEN-YUEH provides customers with professional air knife consulting services.

If customers have other material and function requirements, SHEN-YUEH can customize design and manufacturing according to your specifications.

Product Features

The high-pressure airflow produced by air knives has uniform air pressure and low-pressure loss, which can be used in surface liquid scraping, blowing, dust removal, cleaning, drying, cooling and other processes. It can also be used as an air curtain for isolation, film blowing and chips blowing, etc., with a double drying efficiency.

Especially suitable for semiconductors, panels, film production lines, ultrasonic cleaning, glass cleaning machines, circuit boards, electroplating pieces, films, coating, non-ferrous metal plate / wire rod production and other industries, as well as in various processes such as get rid of dew, adjustable air outlet design to blown air out in a single direction, and others, to meet diverse production needs.

Product Applications

- Bottom Plate Drying

- Sheet Drying

- Turbulent Flow

- Air Mixing

- Drying After Parts Cleaning

- Cooling

- Surface Liquid Scraping

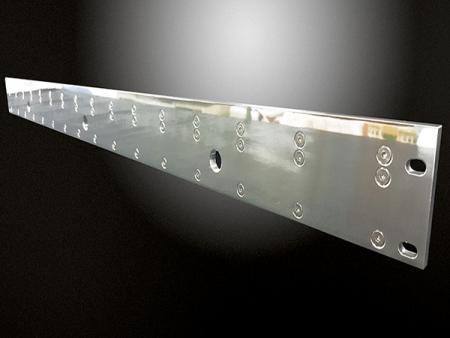

Product Gallery

SUS Air Knife. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Air Knife, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.