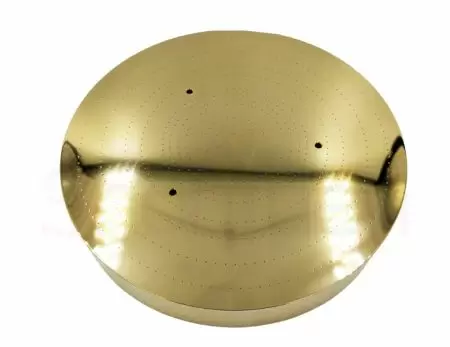

Wafer prober Golden(Hot) chuck

The Wafer Prober Golden(Hot) Chuck made by Shen-Yueh is used in the Tokyo seimitsu (accretech) Prober UF200, mainly used to heat wafer probe devices (manual, semi-automatic, or fully automatic). This product can be cooled and raised for wafer testing (-30 ° C to 200 ° C). It is a device used for probe testing. The surface usually has a special coating to increase conductivity. The picture shows chuck improved for customers. There are more than 600 micro vacuum adsorption holes which increase the adsorption capacity of the wafer and improves the accuracy of electrical testing.

Product Feature

1. High-temperature performance: It can operate at temperatures of up to 200°C and can meet a variety of high-temperature heating requirements.

2. Heat quickly: With its rapid heating and cooling capabilities, the wafers can be quickly heated to the desired temperature, thereby increasing production efficiency and reducing production costs.

3. Accuracy Control: With high-precision temperature control and temperature uniformity, micron-level heating accuracy and flatness can be achieved, thus improving test quality and accuracy.

4. Easy to install: Easy to install, usually compatible with common semiconductor test equipment, and can be integrated with other test equipment.

5. High reliability: The structure design is stable and can maintain a long stable working state, thereby improving test efficiency and reducing failure rate.

In general, Wafer Prober Golden(Hot) Chuck is a high-temperature heating clamping device with a high- temperature performance, is fast heating, has precision control,

an easy installation and a high reliability, which can meet the heating requirements during semiconductor testing, thereby improving test quality and accuracy.

Product Specifications

- Wafer Size: 6 "(150 mm)、8" (200 mm)、12 "(300 mm)

- The Wafer Prober Golden(Hot) Chuck can be customized according to the customer's needs.

The Wafer Prober Golden(Hot) Chuck made by Shen-Yueh can effectively improve electrical conductivity. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, , CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.