TFT-LCD Spring Roller

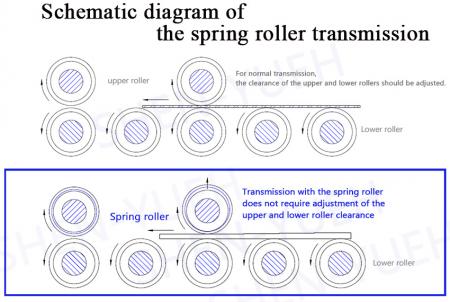

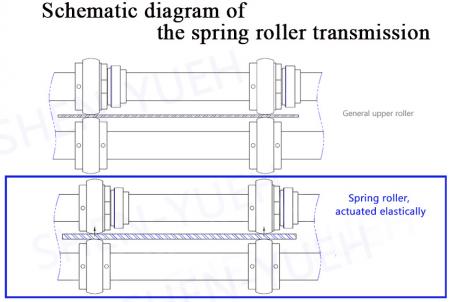

SHEN-YUEH's spring rollers are patented (Patent No. M415896 / M595110). As TFT-LCD glass substrate has varied thickness specifications, when engineers replace glass of different thicknesses it can be very time-consuming adjusting the gap between the upper and lower delivery rollers. After SHEN-YUEH replaces the upper roller with the spring roller, the upper and lower roller gap (holder gap) does not need adjusted, greatly reducing the time spent for engineers and the damage rate.

Product Application

Spring rollers are used in the TFT-LCD panel industry and automatic transmission systems. Due to the thinness of glass substrate and improper adjustment between the upper and lower transmission rollers in the transmission process, damage can easily occur. The damage rate of glass substrate can be reduced by using spring rollers.

We can design different materials and specifications according to customers' requirements, including PVC, PTFE, PEEK and so on.

Product Specifications

| Type | Optional Materials |

|---|---|

| Body | ● Metal: - SUS stainless steel (304 / 316 / 316L) ● Engineering plastics: - PVC (temperature up to 40 ~ 50°C) - PEEK (temperature up to 260 ~ 300°C) |

| Roller | ● Engineering plastics: -UPE (good wear resistance, temperature resistance up to 100 ~ 120°C) - PVC (used at room temperature, temperature resistance up to 40 ~ 50°C) - PTFE (soft material, excellent acid and alkali resistance, temperature resistance up to 260 ~ 300°C) - PEEK (good wear resistance, fire resistance, electrical property, temperature resistance of -60 ~ 300°C) |

Spring Roller Operation Description

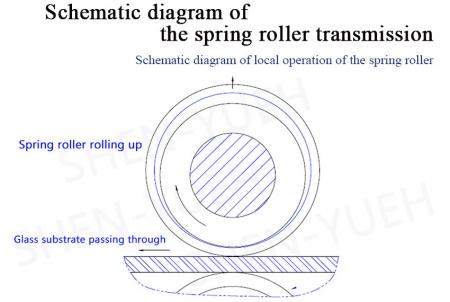

- Spring roller in transmission.

- Difference between general rollers and spring rollers.

- Spring roller local operation diagram.

- Files Download

SHEN-YUEH Patented Spring Roller

SHEN-YUEH Spring Roller Patent Certificate M415896 / M595110.

Download

We offer various spring rollers and materials for panels and automatic transfer equipment. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, TFT-LCD Spring Roller, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.