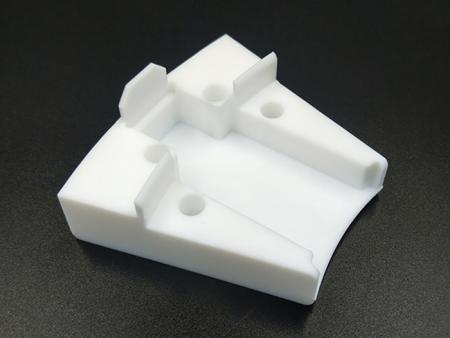

CNC Plastic Machining

SHEN-YUEH has been involved in engineering plastic machining for over ten years. We manufacture customer parts by plastic machining service using CNC milling machine and lathe, we also have 3D scanning and testing equipment. Excellent equipment needs to be operated by professional technicians.

SHEN-YUEH's technicians are skilled in CNC equipment operation and have rich experience in advanced engineering plastic and general engineering plastic processing (such as PI, PEEK, TORLON, PTFE, PPS, PEI, UPE, PVC, PETP, PC and PP). They have mastered tolerance dimension precision required in engineering plastic processing.

Plastic Machining Applied in Multiple Industries

All related semiconductor equipment, TFT-LCD equipment, solar equipment, medical machinery equipment, food machinery equipment, precision parts and fixture design and manufacturing are within our services. We also provide 3D drawing and scanning to serve our customers in the development of new components and reverse engineering parts in the shortest possible time.

SHEN-YUEH has set up a professional team to solve problems for customers. The team consists of professionals who can provide technical information about designs, processing, welding, and inspections so you can trust our qualified partners to help you find processing solutions.

PEEK Plastic Machining

PEEK Plastic processing tolerance precision can be controlled to 0.05mm, special precision...

DetailsPBI Plastic Processing

Shen-Yueh's PBI engineering plastic parts can be applied in semiconductor etching, sputtering,...

DetailsVESPEL CR6110/CR6100 Plastic Processing

We specialize in the processing of VESPEL CR6110/6100 plastics, providing tailor-made solutions...

DetailsPI Plastic Machining

PI Plastic machining parts manufactured by SHEN-YUEH CNC are mainly used in semiconductor or TFT-LCD...

DetailsPPS Plastic Machining

PPS Plastic Machined Parts can be customized to match your specifications. PPS Plastic material...

DetailsPolypropylene Machining

Our company specialize in polypropylene machining and processing for semiconductor equipment...

DetailsPTFE Plastic CNC Machining

PTFE material is most widely used in fluorine engineering plastics as it has a low hardness,...

DetailsPVC Plastic CNC Machining

PVC Plastic for CNC Machining is the most common engineering plastic with characteristics of acid...

DetailsConductivity/ESD Prevention Engineering Plastic Machining

Shen-Yueh offers the service of conductivity/ESD engineering plastics processing, which can be used...

DetailsCNC Plastic Machining | CNC Metal & Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, CNC Plastic Machining, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.