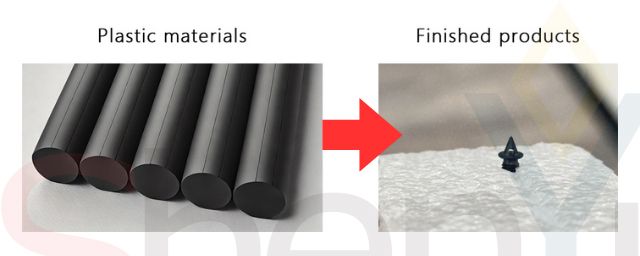

PBI Plastic Processing

Shen-Yueh's PBI engineering plastic parts can be applied in semiconductor etching, sputtering, CVD, PVD, and wafer and panel contact components. PBI plastic itself features the most advanced plastic characteristics, the plastic itself can be used for a prolong period of time at 430 degrees Celsius, and can withstand transient temperatures of up to 500 degrees Celsius, in accordance with its excellent characteristics, it can be used for a longer period of time compared to PEEK.

We offer PBI professional plastic processing information consultations, feel free to contact us using the form below, we hope to be of service to you.

We offer PBI plastic processing services

- Over 10 Years of Experience:

With over 10 years of experience in PBI processing for technology companies, we have accumulated extensive technical expertise and industry knowledge. - Custom Processing:

We offer customized PBI products tailored to customer needs, including special shapes and sizes. - Precision Machining:

We provide precise CNC machining services to meet high-accuracy design requirements. - Small Batch Production:

We support small batch production to cater to customers' diverse needs. - Technical Support:

We offer professional technical consultation and after-sales service to help customers resolve issues during the processing stages.

Advantages of PBI Engineering Plastic

- Withstands long-term use temperature of 430°C and transient temperature of 500°C

- Excellent mechanical strength and hardness

- Good chemical resistance

- High purity, good electrical insulation and dielectric properties

- Excellent wear resistance

- Low thermal expansion rate

- Radiation resistant, low combustibility

PBI Processing Performance

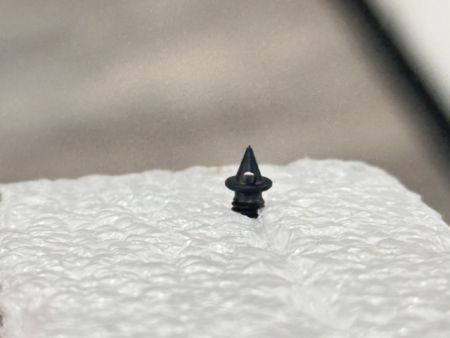

Shen-Yueh's PBI wafer pins can withstand temperatures up to 430°C and have a remarkably long service life. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, PBI Plastic Processing, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.