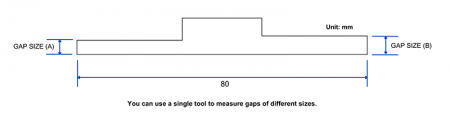

Gap check Tool(T-type)

Our Gap Check Tool, made of high-performance PEEK (Polyether Ether Ketone), offers exceptional scratch and wear resistance, protecting workpiece surfaces and ensuring stable measurements. Withstanding temperatures up to 240°C and resistant to acid, alkali, and particles, it is ideal for cleanroom environments. The T-type design enables dual-sided gap measurement, boosting efficiency and eliminating frequent adjustments, making it perfect for quick inspections. Customization services are available to meet your specific needs—contact us for tailored solutions!

Product Advantages

- Acid and alkali resistance

- Heat resistance up to 240°C

- Suitable for cleanroom environments

- Customizable for different sizes

- Better protection for components compared to metal, preventing scratches

- T-shaped dual-size gap design reduces gap piece replacement time

- Small-scale customization available, reducing inventory pressure

Product Specifications

- Material: High-performance plastic PEEK

- Gap Specifications: Customizable to your needs. Please fill out the form below to contact us.

Gap Check Tool (T-type) Heat resistant to 240°C, scratch-resistant, particle-free, ideal for cleanrooms and acid-alkaline environments. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Gap check Tool(T-type), CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.