Titanium Alloy CNC Machining

Pure Titanium / Titanium Alloy / α Alloy Titanium / α + β Alloy Titanium / β Alloy Titanium

Titanium alloy CNC Machining products feature small expansion coefficient, durable wear, non-magnetic material and lower specific gravity, are widely used in the electronics, biotechnology and aerospace industries for high acid- and alkali-resistance and weight-reduction parts. The general tolerance of our CNC titanium alloy products can reach a precision of 0.02mm (special requirements can be discussed).

Titanium Alloy Application

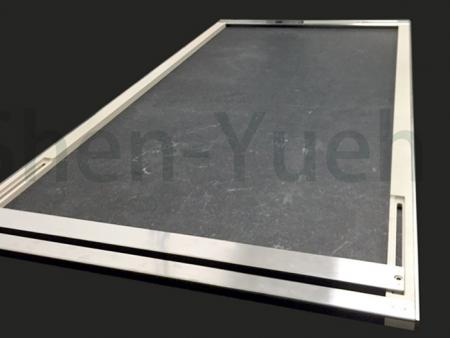

Titanium alloy is more widely used at present, including in automobile parts, sports and medical equipment, glasses, watches and in other industries that make products for general consumer use. SHEN-YUEH's titanium alloy products are used in the biotech and panel industries. The titanium framework used in the FMM process has good quality, a bright surface, and precise size, with much scope for adjustment in the design based on customer's process problems.

Titanium Alloy Features

1. Superior Physical Features: Low density, lightweight, small thermal expansion coefficient, no magnetic conductivity, high electrical resistivity, low thermal conductivity.

2. Mechanical Properties: High temperature resistance, low metal fatigue, good toughness, high strength.

3. Chemical Properties: Corrosion resistance, latent change resistance, oxidation resistance, non-toxic, antimicrobial resistance.

Titanium Alloy Model

- α alloys

α alloys are single-phase alloys formed by a solid solution of α phase stable elements and neutral elements in α phase. The most representative alloy is Ti-5Al-2.5Sn. This alloy has stable properties at high and low temperatures, good ductility and potential resistance. - α + β alloys

In α + β alloys, the content of α and β phases is greatly affected by α and β stable elements, but the properties are also significantly different. When the content of β phase is low, the alloy behaves like an α alloy, and when the content of the α phase is low, the alloy behaves like a β alloy. Ti-6Al-4V is the most typical α + β alloy. Ti-6Al-6V-2Sn and Ti-6Al-2Sn-4Zr-6Mo have more β-phase content. The dosage of Ti-6Al-4V accounts for about 70% of the dosage of all titanium alloys. - β alloys

β alloy is quasi-stable body-centered cubic (BCC) structure at room temperature and is a single β phase alloy. The cooling machinability of these alloys is better than that of α + β alloys. After aging hardening treatment, the tensile strength can reach 150kgf/mm² and yield strength 140kgf/mm². Typical alloys are Ti-15V-3Cr-3SU-3Al, Ti-10V-2Fe-3Al and Ti-13V-11Cr-3Al.

Titanium Alloy Processing Performance

SHEN-YUEH's CNC high-precision, aesthetically pleasing processed titanium parts are often used in semiconductor and biochemical industries. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Titanium Alloy CNC Machining, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.